Flange management

We can provide a ‘bolt load’ calculation, where we will advise the required bolt load. Should a bolt load calculation be required, we require a number of details of the flanged connection, such as:

- Flange diameter

- Flange pressure rating

- Amount of bolts

- Grip length

- Bolt diameter

- Type of gasket and material

- Nut and Bolt material

- friction coëfficient of the bolt lubrication

- Operational temperature

We can provide a ‘bolt load’ calculation, where we will advise the required bolt load. Should a bolt load calculation be required, we require a number of details of the flanged connection, such as:

- Flange diameter

- Flange pressure rating

- Amount of bolts

- Grip length

- Bolt diameter

- Type of gasket and material

- Nut and Bolt material

- friction coëfficient of the bolt lubrication

- Operational temperature

A fast economic way of removing seized or corroded nuts which saves time during critical activities such as turnarounds and stops. Hydraulic nut splitting has the advantage of not needing a hot work permit. The nut splitter may be used with either a hand operated or air drive pump unit.

A fast economic way of removing seized or corroded nuts which saves time during critical activities such as turnarounds and stops. Hydraulic nut splitting has the advantage of not needing a hot work permit. The nut splitter may be used with either a hand operated or air drive pump unit.

Flanges are tightened according to “CBT-001 Assembly & Tightening of Bolted Flanged Connections” procedure. The tools are utilized according to the manufacturer’s instructions in which all relevant safety standards are complied with. For every flange to be tightened under controlled conditions within a project, a written protocol/procedure will be submitted to our technician with the required values. After the controlled tightening of the flanged connection, a flange-label will be applied referring to a flange report that will be submitted to the customer for approval that the flange has been tightened correctly. A copy of the calibration certificate of the utilized pump, will be handed over.

Flanges are tightened according to “CBT-001 Assembly & Tightening of Bolted Flanged Connections” procedure. The tools are utilized according to the manufacturer’s instructions in which all relevant safety standards are complied with. For every flange to be tightened under controlled conditions within a project, a written protocol/procedure will be submitted to our technician with the required values. After the controlled tightening of the flanged connection, a flange-label will be applied referring to a flange report that will be submitted to the customer for approval that the flange has been tightened correctly. A copy of the calibration certificate of the utilized pump, will be handed over.

These tensioners have an overload safety feature and two connections. Because of this only 1 t-piece per assembly is required. To date this is the best way to tighten flange connections. By using this method the bolts are ‘pulled’ to the required value, resulting in an even force on all sides of the flange, assuring that the flanges are equally pulled to one another. We have a range of tensioners from ¾” to 4” bolt size.

These tensioners have an overload safety feature and two connections. Because of this only 1 t-piece per assembly is required. To date this is the best way to tighten flange connections. By using this method the bolts are ‘pulled’ to the required value, resulting in an even force on all sides of the flange, assuring that the flanges are equally pulled to one another. We have a range of tensioners from ¾” to 4” bolt size.

Flanges are tightened according to “CBT – 001 Assembly & Tightening of Bolted Flanged Connections” procedure. The tools are utilized according to the manufacturer’s instructions and all relevant safety standards are complied with. Before a flange is tightened, a written protocol with the required values will be submitted to our technician. After the controlled tightening of the flanged connection, a flange-label will be applied referring to a flange report that will be submitted to the customer for approval that the flange has been tightened correctly. A copy of the calibration certificate of the utilized pump will be handed over. After the controlled tightening of the flanged connection a flange-label, referring to a flange report, will be applied. The report will be submitted to a customer for approval. A copy of the calibration certificate of the utilized pump will also be handed over.

Flanges are tightened according to “CBT – 001 Assembly & Tightening of Bolted Flanged Connections” procedure. The tools are utilized according to the manufacturer’s instructions and all relevant safety standards are complied with. Before a flange is tightened, a written protocol with the required values will be submitted to our technician. After the controlled tightening of the flanged connection, a flange-label will be applied referring to a flange report that will be submitted to the customer for approval that the flange has been tightened correctly. A copy of the calibration certificate of the utilized pump will be handed over. After the controlled tightening of the flanged connection a flange-label, referring to a flange report, will be applied. The report will be submitted to a customer for approval. A copy of the calibration certificate of the utilized pump will also be handed over.

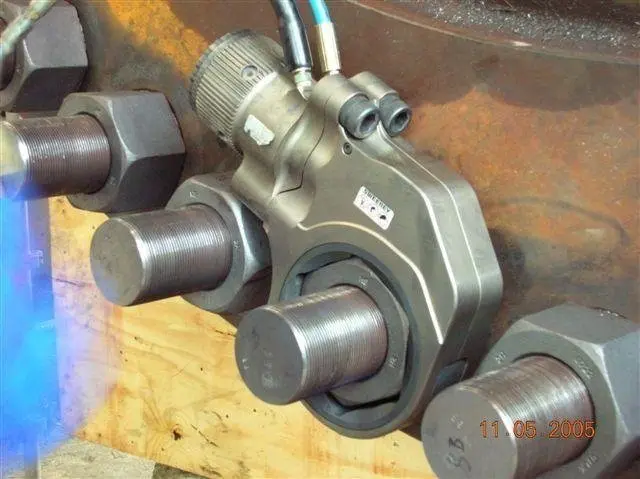

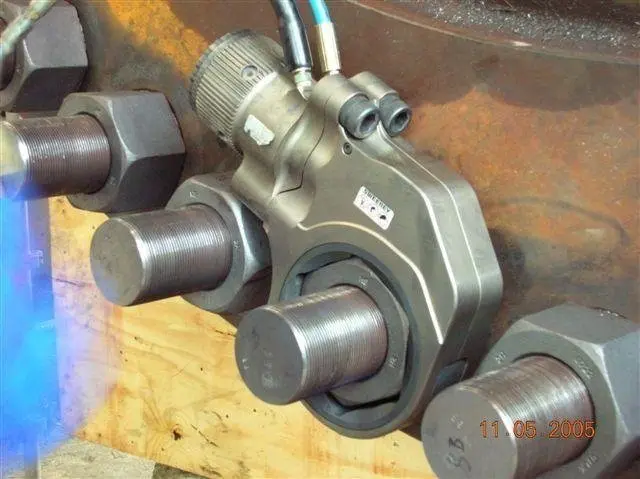

This light weight safe, torque equipment can be used with either a socket or a low profile cassette. From 166Nm through till 38516Nm.

Hytorc Stealth

This light weight safe, torque equipment uses a low profile cassette. From 166Nm through till 42516Nm. This is the ‘top’model from Hytorc

This light weight safe, torque equipment can be used with either a socket or a low profile cassette. From 166Nm through till 38516Nm.

Hytorc Stealth

This light weight safe, torque equipment uses a low profile cassette. From 166Nm through till 42516Nm. This is the ‘top’model from Hytorc